Advantages of L-Type Single Girder Gantry Crane

1. Robust and Compact Structure

- Features a box-shaped gantry framework that delivers exceptional durability and stability for heavy-load operations

- L-shaped leg configuration maximizes vertical working space while maintaining excellent spanning capability

- Single-girder bias track design combines lightweight construction with reliable strength, suitable for applications up to 50t capacity and 35m span

2. Adaptable and Secure Operation

- Offers multiple control interfaces including cabin operation, remote control, and pendant line systems

- Optimized trolley movement with:

- Vertical reaction wheel mechanism (for loads under 20t)

- Horizontal reaction wheel system (for loads exceeding 20t)

- Precision hook speed regulation ensures safe and efficient workspace utilization

3. Operator-Focused Safety and Comfort

- Enclosed cabin with ergonomic design features adjustable seating, insulated flooring, and safety glass

- Available enhancements include climate control, alarm systems, fire suppression equipment, and communication devices

4. Economical Installation and Operation

- Simplified structural design reduces weight compared to double-girder alternatives, lowering production and transportation expenses

- Rapid assembly process utilizing bolted sill beams and leg components with under-slot steel hoist mounting

5. Versatile Application Range

- Excellent for handling steel ladles, extended tubing, and oversized materials due to L-leg configuration that facilitates smooth trolley movement and cargo rotation

- Widely implemented in storage facilities, manufacturing plants, and construction sites owing to compact dimensions and substantial lifting capacity

Key Characteristics

- Integrated overload and low-voltage safety systems

- Dual control options (pendant + remote)

- Minimal maintenance requirements with reduced operational downtime

- Superior spanning performance in confined areas

Comparative Advantage

The L-Type Single Girder Gantry Crane provides a lightweight, cost-efficient alternative to double-girder models while maintaining strong performance metrics, making it ideal for medium-duty lifting applications requiring space optimization and maneuverability.

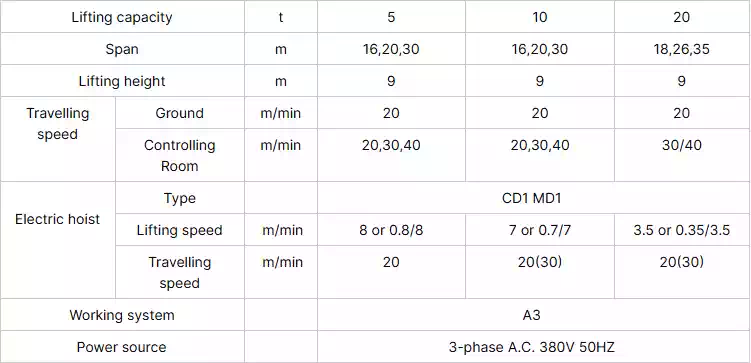

Technical Specifications

Engineered to maximize utilization of space beneath the main girder, this crane excels in outdoor material handling scenarios. It supports both ground-level and cabin control modes, with customization options for specialized attachments including grabs, electromagnetic devices, and custom trays.

Implementation Scenarios

- Hook configurations: General material handling in open storage areas and railway sidings

- Industry applications: Stone processing, construction materials, shipbuilding, metallurgical plants, storage yards, and building projects

Safety Systems

- Load monitoring with overload alert

- Upper/lower travel limit switches

- Polyurethane impact absorption

- Dual control mode selection

- Voltage protection

- Emergency braking

- Current overload protection

Product Attributes

- Simplified manufacturing and installation with optimized stress distribution

- Compact design with some limitation in clearance beyond leg structures

- Streamlined production process

- Comprehensive safety protocols including emergency stop, circuit protection, and phase sequencing

- Independent control of lifting, trolley, and gantry functions

- Adjustable trolley limit switches

- Integrated cable management system

- Standard load limiting and position control devices