Introduction of Port Rail Mounted Container Gantry Crane

Electric-powered RMG cranes operate on fixed rail tracks, offering an efficient and eco-friendly solution for ports and container yards. Compared to diesel-powered alternatives, they provide lower operating costs, higher stacking density, and improved handling precision. Their rail-bound design supports automation and enables optimized yard space utilization, with optional remote control for 24/7 operation.

A newer innovation, the Nested RMG (Double-Rail RMG), allows multiple cranes to operate in the same area, enhancing operational flexibility.

Full Automation Examples:

Remote-controlled cranes (±2 cm accuracy via 5G)

Autonomous guided vehicles using RTK navigation

Smart operational systems boosting efficiency by up to 40%

Features of Port Rail Mounted Container Gantry Crane

Key Benefits

Strong Lifting Capacity: Handles 20' and 40' containers; twin-lift capable

Electric Operation: Zero emissions with reduced operating costs

High-Speed Performance: Rapid movement even under full load

Precise Control: Specialized drive systems minimize load sway

Durable Construction: Robust steel wheels and heavy-duty structure ensure long service life

Our RMG Features

Advanced control systems (Siemens PLC / Schneider)

Remote Crane Monitoring System (RCMS)

Customizable hoisting (single/double drum)

High-precision spreader

Circular trolley for improved load balance

Anti-sway and safety systems

Ergonomic cabin with 360° visibility

Specialized Models for Specific Markets

New Smart Cabin Design

Enhanced visibility for intermodal operations

Modular design for faster delivery

Automation-ready for future upgrades

Dynamic Load Control (ALC) system enables efficient spreader-only movement without full crane travel

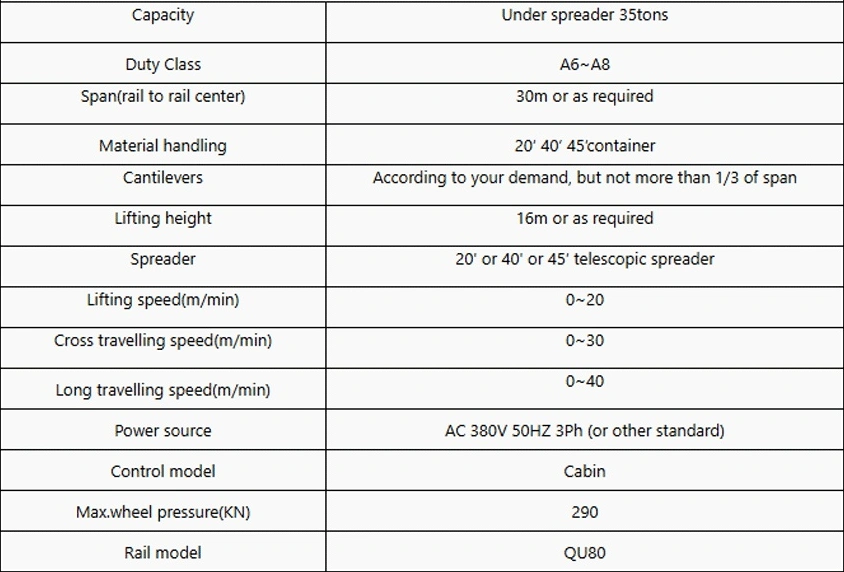

Technical Parameters of Port Rail Mounted Container Gantry Crane

Our double-beam RMG cranes offer:

40.5-ton capacity

45m span | 18.9m lifting height

"Stack 5, pass 6" capability (4-high stacking with clearance)

Fertilizer container handling package:

Video monitoring

Intelligent lightning protection

Anti-lift safety system

8-rope anti-sway technology

Automatic trolley locking

Why Choose Our RMG Cranes?

✔ Customized layouts for specific yard needs

✔ Energy-efficient electric operation

✔ Compliant with global safety standards

✔ Accelerated container handling

✔ Reduced maintenance requirements

✔ Extended equipment service life