Introduction For MG Gantry Crane

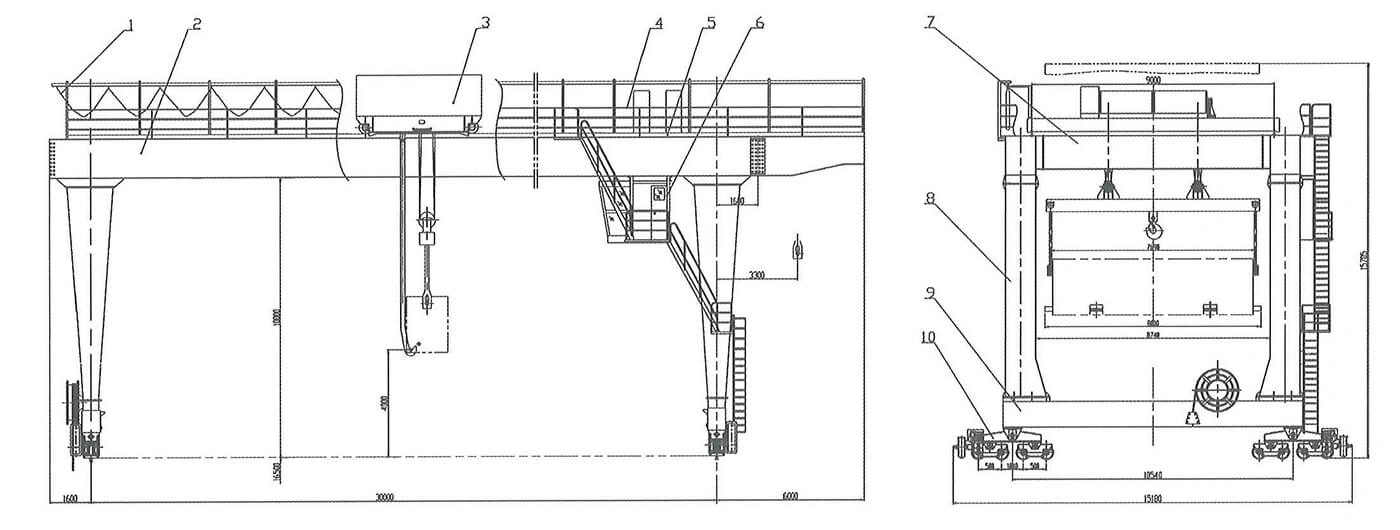

The MG-Type Double Girder Hook Gantry Crane is engineered for heavy-duty material handling in demanding environments. Its robust construction includes a welded box-girder bridge frame, independent travel mechanisms, a high-capacity trolley, and fully integrated electrical systems. All operations are conveniently controlled from the operator's cabin.

Features of MG Gantry Crane

DESIGN ADVANTAGES

Superior MG-Type Structure

The U-shaped gantry design provides exceptional leg clearance, facilitating the handling of long and oversized materials like containers, steel beams, and timber. This innovative design eliminates the need for a saddle frame, resulting in a more compact overall machine length.

Heavy-Duty Construction

Main structure fabricated from Q235B/Q345B carbon steel

Premium hoisting system with Class F motor, precision reducer, and reliable brakes

High-quality ZPMC hooks and vacuum-cast wheels ensure smooth operation

Advanced Drive System

Motors compliant with FEM & HMI standards deliver high-speed, energy-efficient performance with minimal noise. The box-type main beam connects to end beams using high-strength bolts for simplified installation.

Comprehensive Safety Systems

Overload protection

Multiple travel limit switches

Emergency stop functionality

Anemometer for wind speed monitoring

Power failure protection devices

Customization & Compliance

Manufactured to meet GB/T3811-2008, ISO, CE, and GOST standards. Available in specialized versions for hazardous environments and compatible with various lifting attachments (slings, magnets, etc.).

Global Service Support

Our technical experts provide worldwide installation supervision and comprehensive operator training.

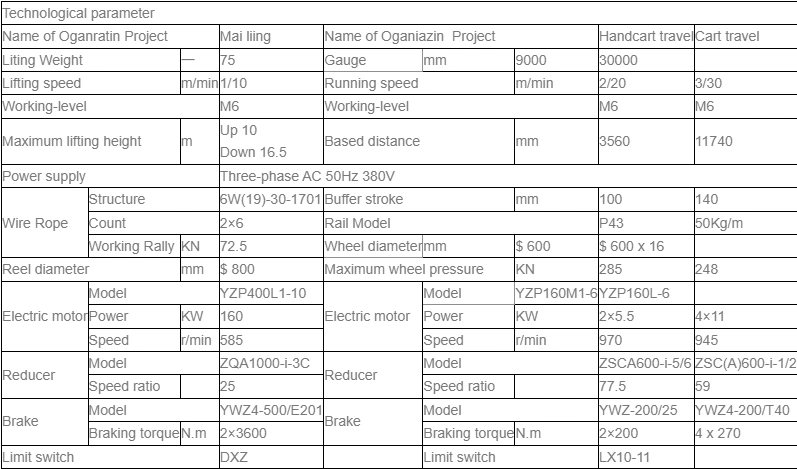

Product Parameters of MG Gantry Crane

Key Specifications:

Lifting Capacity:10 - 400/10 tons

Operating Temperature: -25°C to +40°C

Leg Clearance: 7+ meters for handling oversized cargo

Power Options: Cable reel or sliding contact line (recommended)

Primary Applications:

Ideal for railway freight yards, port terminals, outdoor storage areas, and container stations, providing reliable performance for heavy load transportation and standard loading/unloading tasks.