Introduction of New Electric Hook Bridge Crane

The KSQ series double girder overhead crane is engineered to deliver precision and reliability for demanding industrial applications. Its design, manufacturing, and quality inspection adhere strictly to the latest national standards (GB) while also incorporating key international norms such as FEM, DIN, and IEC. Certified under ISO and CE, this crane ensures stable and accurate lifting and travel movements.

Compared to conventional QD-type bridge cranes, the KSQ model offers a significant reduction in overall weight (15–30%) and maximum wheel pressure (10–35%), easing structural demands on your workshop and lowering overall project costs. Key components include a high-precision, hard-tooth-surface reducer gear set, forged wheels, and a variable-frequency drive system. These features make the KSQ series a modern, high-performance upgrade to traditional overhead cranes.

Features of New Electric Hook Bridge Crane

Design & Compliance

Our cranes are manufactured in accordance with the following standards:

GB/T10183-2005: Manufacturing and rail installation tolerances

GB/T5905-1986: Crane testing specifications

JB/T4315-1997: Electric control equipment

GB8918-2006: Wire rope for critical applications

GB/T700-2006 & GB/T1591-2008: Structural steel specifications

JB928-1994 & GB11345-1989: Weld inspection standards

Structure & Performance

The KSQ double girder crane consists of a twin-girder frame, end trucks for bridge movement, and a top-running trolley with independent lifting and travel drives. Motors, reducers, and brakes are configured as separate units, enabling higher duty cycles (A3–A8 per ISO) and faster, more responsive speed control.

With standard 10-step adjustable speed regulation, the crane operates smoothly even at very low speeds—ideal for precision load positioning and delicate handling tasks.

Safety Systems Include:

Overload protection with automatic hoist cutoff

Travel limits with preliminary/final switches or infrared anti-collision

Anti-fall protection for Three-in-One electric motors

Emergency stop control via main contactor

Durable polyurethane buffers to prevent over-travel

Safety hook latches to secure loads

Audible and visual pre-operation alarms

Rain covers for outdoor lifting mechanisms and electric cabinets

Protective earth conductor and voltage/current overload protection

(Contact us for a full safety feature list)

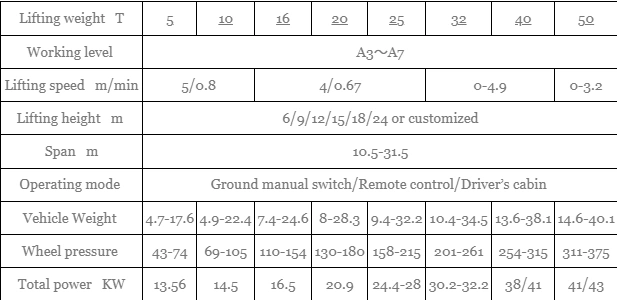

Technical Parameters of New Electric Hook Bridge Crane

To receive a customized product recommendation, please provide the following details:

Lifting capacity

Span (rail center to center)

Lifting height (hook path)

Power supply specifications

Working environment (material type, temperature, etc.)