Introduction of New Types Single Girder Bridge Crane

Designed as a next-generation material handling system, the European Single Girder Overhead Crane integrates smart technology to redefine efficiency in industrial operations. At its core, the lifting mechanism features a European-style ND steel wire rope electric hoist—engineered for reliability and paired with dual-speed lifting capabilities, allowing operators to switch between high-speed transfers for light loads and precise, low-speed movements for heavy or delicate items.

For seamless traversal, both cross and long traveling systems are powered by infinitely variable frequency (VF) motors. This technology eliminates jerky starts and stops, ensuring smooth, controlled movement across the crane’s span—reducing wear on components and minimizing the risk of load instability during transport.

Features of New Types Single Girder Bridge Crane

Compliance & Safety: Built to Global Standards

Every aspect of this crane adheres to stringent international standards, including FEM, DIN, and ISO guidelines. This compliance guarantees exceptional safety, ergonomic operation, and long-term durability. The hoisting mechanism, in particular, is manufactured to meet FEM’s rigorous performance criteria, ensuring consistent, safe lifting even in high-demand environments.

Space-Saving & Cost-Effective Design

One of the crane’s standout features is its compact structural layout. By optimizing the size of key components (such as the hoist trolley and main girder), it occupies significantly less overhead and floor space compared to traditional cranes—ideal for factories or warehouses with limited vertical or horizontal room. This design also translates to lower operational costs: reduced space requirements mean less infrastructure investment, while energy-efficient motors and durable parts cut down on maintenance and utility expenses.

Lightweight Construction:

Reduces structural stress on your facility while maintaining high load-bearing capacity.

Aluminum Alloy Reducer Shell:

Enhances heat dissipation and corrosion resistance, extending the reducer’s lifespan.

Stable, Quiet Operation:

Precision-engineered components and VF motors minimize noise, creating a more comfortable work environment.

Lifetime Lubrication:

Pre-lubricated parts (within the safety service cycle) eliminate the need for frequent re-lubrication, saving time and labor.

Dual-Disk Electromagnetic Brake:

Delivers strong, instant stopping power, enhancing safety during load handling and emergency situations.

Enhanced Durability & Versatility

Robust Wheel Frame Design:

Simplifies balance adjustment and installation, while reinforcing the crane’s overall structural integrity for long-term use.

High-Protection Motors:

Motors feature IP54 protection class and F-class insulation, making them dustproof, water-resistant, and suitable for harsh industrial conditions. An integrated overload protection device adds an extra layer of safety by preventing damage from excessive loads.

Advanced Gear Box:

Custom-designed with helical gears and self-lubricating technology, ensuring smooth power transmission and minimal wear.

Flexible Control Options

Operators can choose between two intuitive control methods:

Pendent Control Panel: Can be attached directly to the hoist trolley for close-range operation or moved independently along the main girder guide for broader visibility.

Remote Control: Allows operators to move freely on the ground, providing a safe, unobstructed view of the load and work area.

Both control systems enable stepless adjustment of lifting and traveling speeds, letting users fine-tune operations to match specific tasks. Additionally, the crane uses thousands of unique frequency points—preventing signal interference even when multiple cranes are operating in the same workshop.

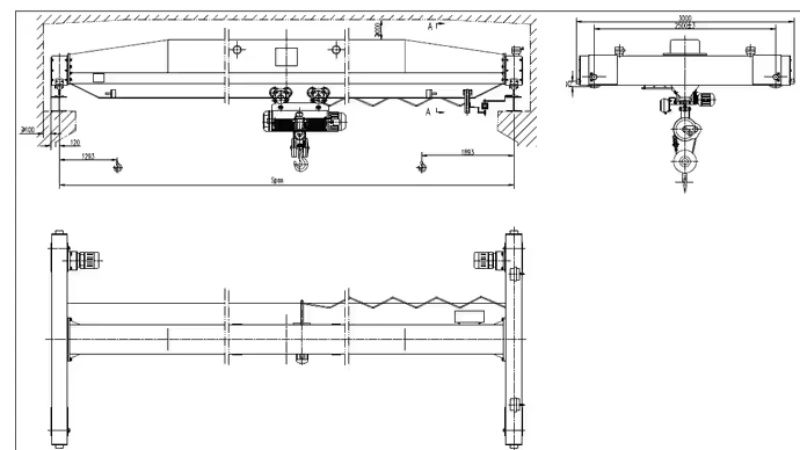

Technical Parameters of New Types Single Girder Bridge Crane

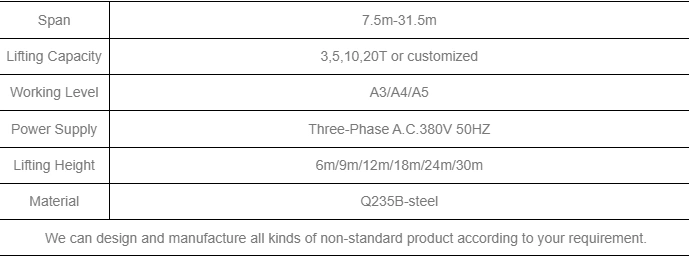

Span: 7.5m-31.5m

Capacity: 1t/2t/3t/5t/10t/16t/20t or customized on demand

Lifting height: 6m/9m/12m/18m/24m/30m

Work duty: A3/A4/A5

Rated voltage: 380V, 50Hz, 3ph AC

Crane control mode: Floor control / Remote control / Cabin room control

Traveling speed: 20-30m/min

Customized Solutions for Your Needs

We understand that every industrial application is unique. To ensure the crane perfectly fits your requirements, please provide the following details when requesting a customization:

Required lifting capacity (e.g., 5t, 10t).

Span length (distance between the crane’s supporting rails).

Lifting height (distance from the hook center to the ground).

Power supply specifications (voltage, phase).

Rail requirements: Do you need rails? If yes, what is the crane’s traveling distance?

Working conditions: Type of material to be lifted (e.g., steel, concrete) and operating temperature range.

Plant drawings (if available) to optimize crane placement and integration.

This European Single Girder Overhead Crane is more than a lifting tool—it’s a smart, cost-effective solution designed to boost productivity, enhance safety, and adapt to your unique industrial needs.