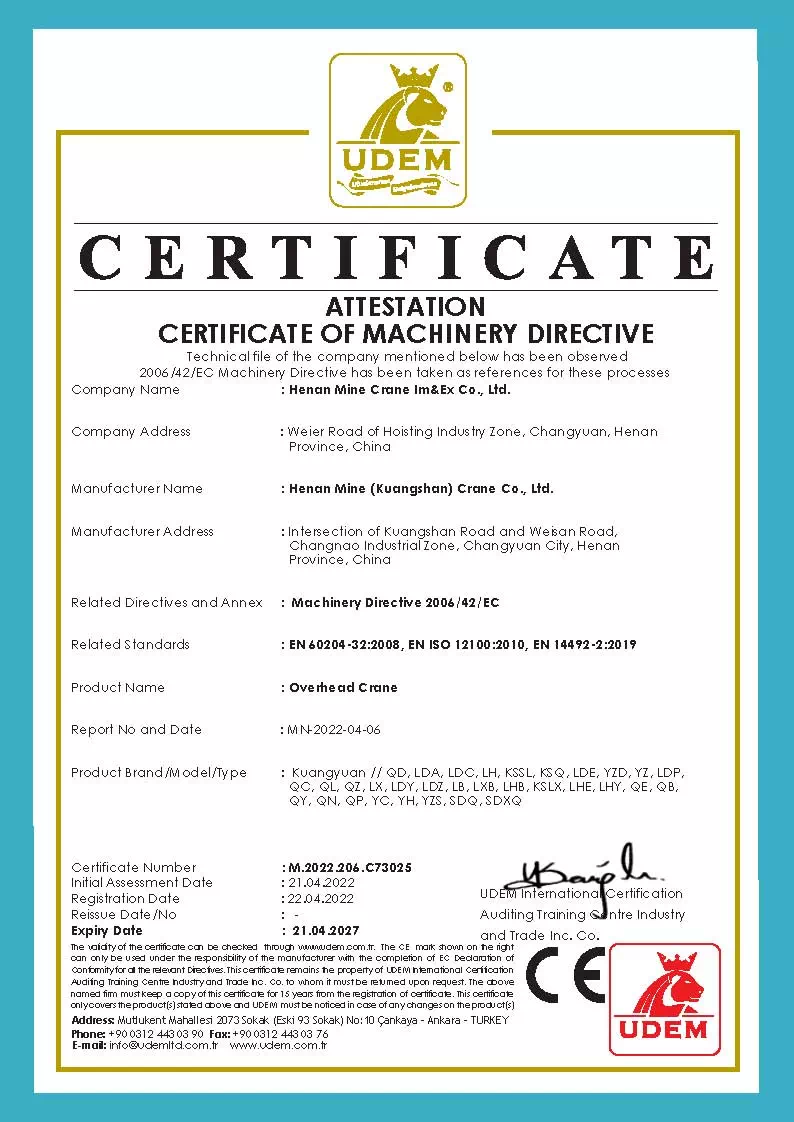

Introduction of 320t Four-Beam Casting Crane

The YZS Casting Bridge Crane is a high-performance solution designed for intensive steel mill operations, including molten steel pouring and slag handling. Its robust four-girder, four-rail construction ensures exceptional structural integrity and longevity.

This crane operates with a dual-crab system for maximum efficiency. The primary crab, moving on the outer rails, utilizes a connecting traverse to securely handle the steel ladle. Meanwhile, the secondary crab, equipped with a hook and operating on the inner rails beneath the main unit, performs precise pouring and auxiliary lifting tasks.

Features of 320t Four-Beam Casting Crane

Key Engineering & Safety Advantages:

Optimized Drive & Structure: The trolley features a reliable four-corner drive mechanism. The entire bridge assembly undergoes specialized integral processing and a secondary assembly protocol. This advanced manufacturing technique relieves internal welding stresses, guaranteeing long-term dimensional stability, precise gauge, and simplified on-site installation.

Enhanced Thermal Management: To protect critical components, the electric panel room is insulated with rock wool and includes an integrated air cooler. A dedicated heat shield is installed along the girder's underside to deflect radiant heat from molten metal.

Comprehensive Safety Systems: Safety is paramount, with multiple integrated protections:

Lifting Security: The main hoist is equipped with an overspeed switch and dual braking systems per lifting point, totaling four brakes for the main lift. The ladle hook design uses multiple wire ropes per pulley for redundant load security.

Operational Controls: The crane includes overload protection, emergency stopping, and travel limits with preliminary and final limit switches.

Electrical Safety: The system is safeguarded by phase sequence, zero position, voltage loss, short-circuit, over-current, and under-voltage protections. Motors feature anti-falling devices, and electrical enclosures boast high IP54/IP55 ratings.

Advanced Instrumentation: A dedicated electronic scale provides accurate weight data, with displays accessible from both the cab and the bridge for operator convenience.

Technical Parameters of 320t Four-Beam Casting Crane

Standard Operational Specifications:

Duty Class: A7

Ambient Temperature: -10°C to +60°C

Power Supply: 3-Phase, 380V, 50Hz (customizable)

Built for heavy-duty performance, the YZS Crane offers a main/auxiliary capacity starting from 125/32 tons, delivering the power, precision, and reliability required for the most challenging industrial environments.